Notes and sketches on the Final Project

The basic idea is to have pressurized clay come into a tee fitting that I can machine out of brass(I have some experience with metal machining and lathe turning). Inside the tee fitting there will be a screw that rotates and pushes the clay downwards through the nozzle piece that can rotate while attached to a belt and pulley system. The nozzle will be 3d printed to allow for easy testing and swift interchangeable designs.

It will print out great clay objects that can be used around the house and hopefully bricks to do architecture with.

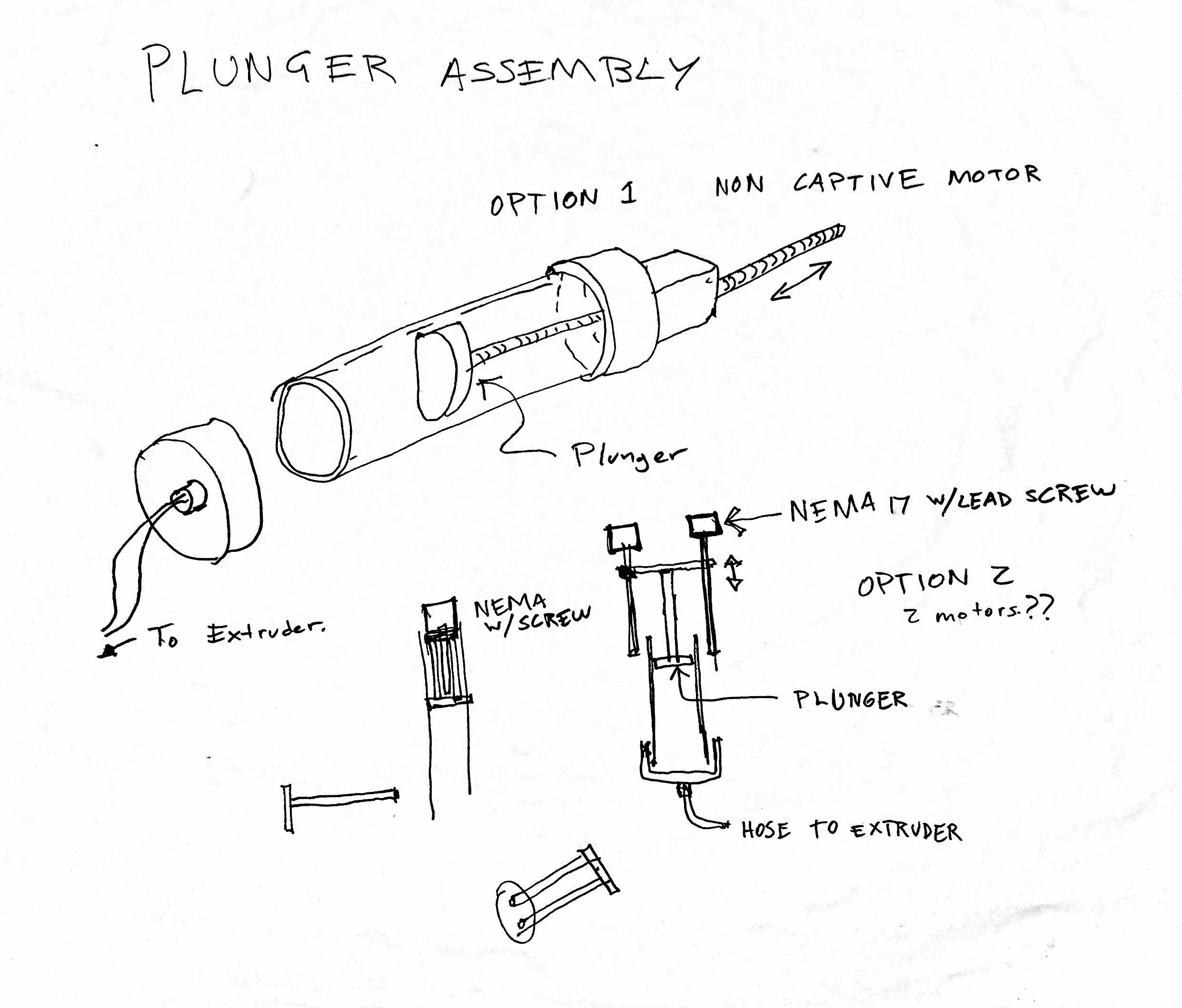

There are two important areas of focus: the first is the end mechanism that does what is described in the diagram, and the second is the mechanism that provides the pressurized clay. I'll try to develop those in parallel and hopefully finish both, but the plan is that the project could work with either of the two systems.